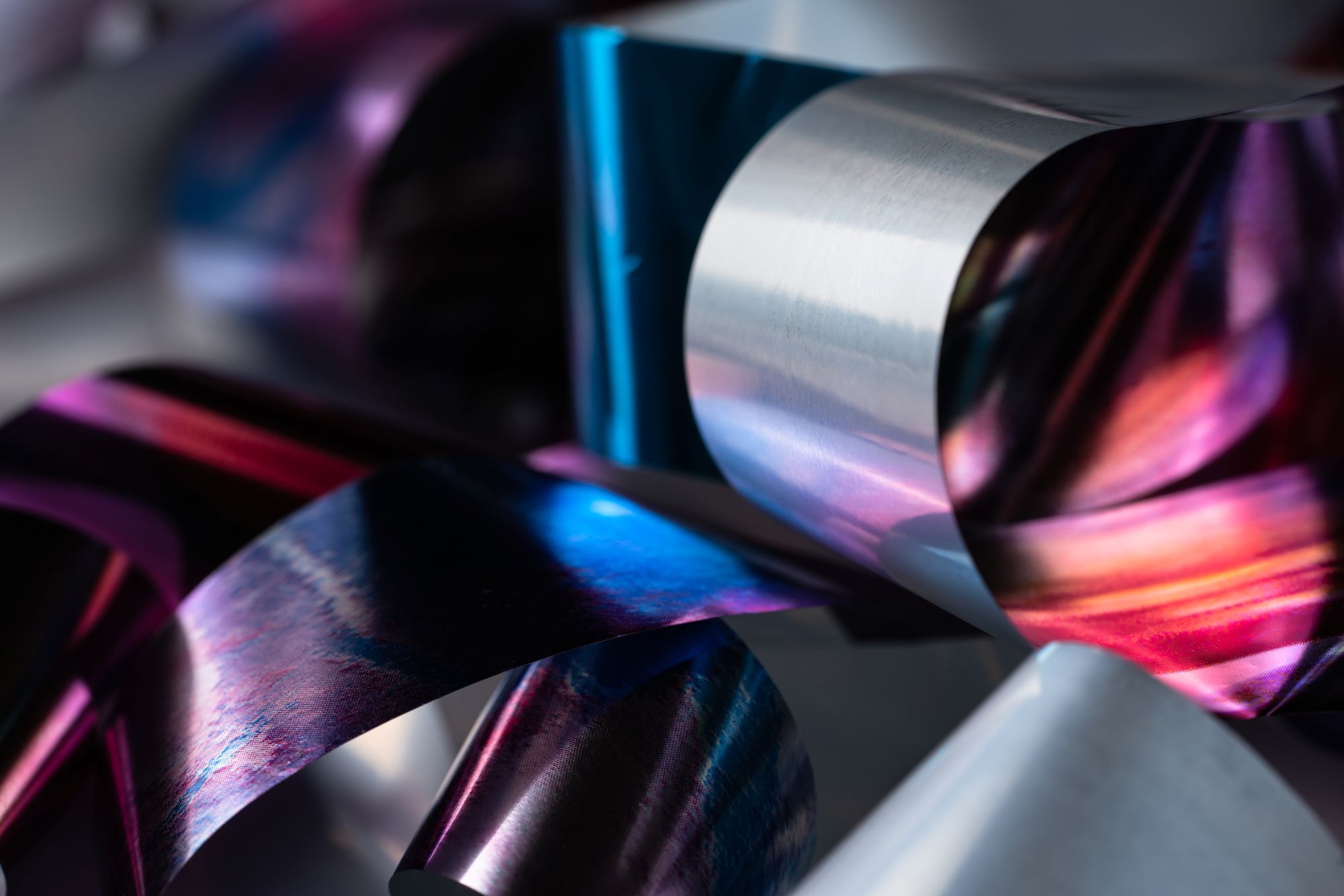

Optimising wire drawing machinery Surfaces: Improving efficiency and durability

Wire drawing is an essential process for many metalworking industries, and the efficiency of this process depends largely on the surface quality of the machinery used.

Advanced coatings, such as nickel, ceramic or tungsten carbide coatings, play a key role in optimising smoothness, reducing wear and ensuring high operational precision. Companies such as Paganoni, a leader in technical coatings, offer innovative solutions to improve the performance of mechanical components in this field.

Surface coatings: Improving smoothness and efficiency

Wire drawing machines, such as capstans, pulleys and guides, are subject to considerable mechanical and thermal stress. The surface roughness of components can generate friction, reduce wire smoothness and accelerate wear. Advanced surface coatings provide an answer to these issues:

- Electroless nickel coatings

Electroless nickel offers exceptional corrosion resistance and a uniform surface, ideal for reducing the coefficient of friction. This treatment provides effective protection against wear and maintains consistent performance over time. Paganoni uses this coating to ensure that cabestans and other crucial components maintain optimum efficiency even in particularly aggressive environments. - Ceramic coatings

Ceramic coatings, such as those based on zirconium oxide or chromium oxide, offer exceptional hardness and high resistance to high temperatures. These materials protect mechanical surfaces from abrasion and thermal damage and are particularly useful in the drawing of non-ferrous metals. - Tungsten carbides (Coldside®)

Coldside®, Paganoni’s patented coating based on tungsten carbides, is one of the most advanced solutions for protecting mechanical components. This material combines extraordinary hardness with low surface roughness, improving wire smoothness and extending the life of machinery.

Quality control techniques: Ensuring uniformity and adhesion

The effectiveness of a surface coating depends not only on the material used, but also on the precision with which it is applied. Rigorous quality control processes are essential to ensure that coatings adhere correctly and provide uniform protection. Paganoni uses advanced techniques to monitor every stage of production, ensuring high standards of reliability and performance.

- Measuring surface roughness

- Using advanced measuring instruments, such as optical or contact profilometers, it is possible to verify that the treated surface has a uniform roughness, reducing critical points where friction or failure could occur.

- Coating adhesion testing

- To ensure a long service life, coatings must adhere perfectly to the surface of the component. Techniques such as the pull-off test or scratch test are used to measure adhesion strength and ensure that coatings can withstand operational stresses.

- Microstructure analysis

- Using technologies such as scanning electron microscopy (SEM), it is possible to examine the microstructure of the coating and detect any defects, such as porosity or inhomogeneity. Paganoni uses these methods to continuously refine its surface treatments, guaranteeing superior results.

Concrete advantages in the wire drawing industry

The application of advanced coatings to wire drawing machinery results in numerous practical advantages:

- Reducedmachine downtime due to reduced maintenance requirements.

- Longer equipment life, maintaining high levels of efficiency even after long periods of use.

- Increased quality of the finished product, with a smoother wire surface free of imperfections.

Paganoni, with its experience and technological solutions, is a reliable partner for companies in the sector. Its coatings such as Coldside® and technologies based on technical ceramics have been successfully adopted by numerous industrial companies, confirming their effectiveness in improving productivity and competitiveness.

Investing in quality for the future

Optimising surfaces in wire drawing machinery is not just a technical issue, but a strategic element in ensuring efficiency, durability and quality of the finished product.

Advanced coatings, such as those offered by Paganoni, are an indispensable solution for meeting the challenges of modern industry, reducing operating costs and improving performance. Innovation and quality control are the key to a more productive and sustainable future in wire drawing processes.